Join us October 11–12, 2024, for camaraderie,

instruction, demos, and more in Des Moines, Iowa.

The exciting new issue of Fine Woodworking!

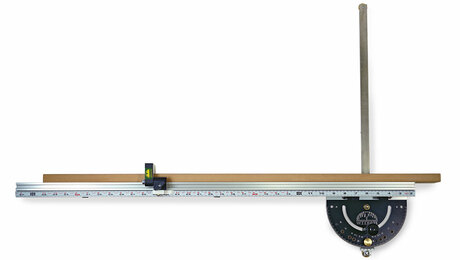

Which way to turn the miter gauge?

From Gerry:

In looking at the images published by the various miter gauge manufacturers, I noticed something that I found contrary to what I have always been told and my own practice. That is: which way should you rotate the miter gauge when cutting a miter such as a 45° miter? I have always rotated my miter gauge clockwise from the normal 90° position so that the wood is trailing the gauge itself. However, most of the manufacturer photos I was seeing have the miter gauge rotated counterclockwise from the perpendicular position with the wood leading the miter gauge into the saw blade. Is there a preferred position for a miter gauge when cutting miters on the table saw?

On the bevel?

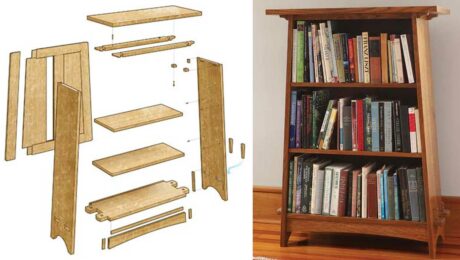

From Stephen:

Hi Anissa (because we can’t have Ben getting all the questions),

I’m looking to build an open bookshelf room divider and wondering if it is a bad idea to bevel the underside of the shelf to give it a lighter look. I have a 1-in.-thick shelf that is 10 in. wide, then on the underside from the center line (where I remove nothing) I plane both edges down to ½ in. I think I should retain a lot of strength in the shelves but that they should look lighter (or maybe they will look weird). What do you think?

|

|

Bench height

From Damon:

My understanding is that the conventional wisdom is for hand tool users to have lower workbenches than power tool users, and that hand planing is a primary reason for that recommendation. Stanley and Lie Nielsen planes both have forward-leaning handles that seem to favor a lower bench, but I use primarily Veritas bench planes. Do the more upright handles of the Veritas planes favor a higher bench? I’m 6′ 3″, and my current bench is 34″ tall.

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to [email protected] for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page.

Sign up for eletters today and get the latest techniques and how-to from Fine Woodworking, plus special offers.