Even if you are new to woodworking, the chances are you have seen floating tenon joinery, the Festool Domino being the most prevalent tool that achieves this. It’s a classic joinery technique modernized for the ease of the modern-day woodworker. But what about a floating dovetail? Yes, they make those, too, and yes, cabinetmakers and other woodworkers have been using them for years, including myself.

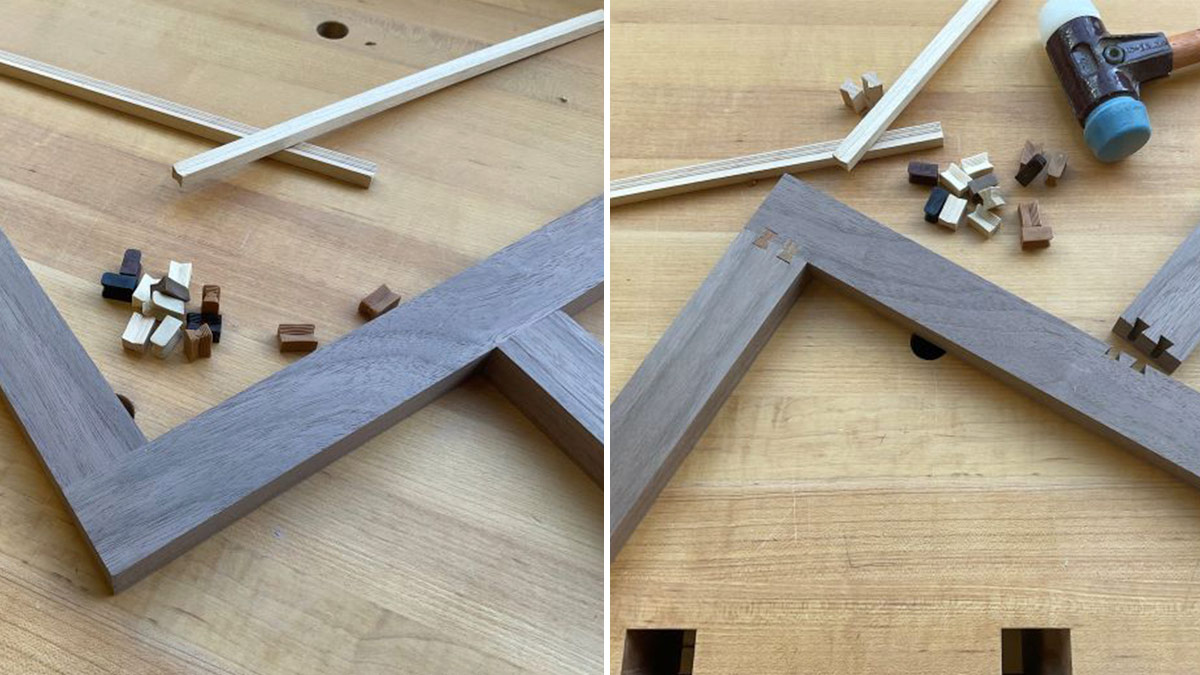

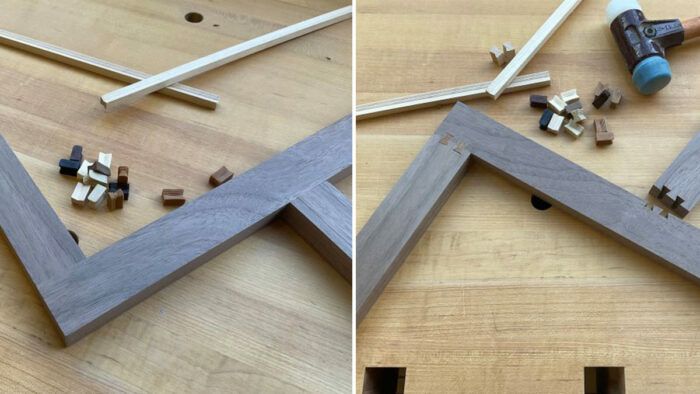

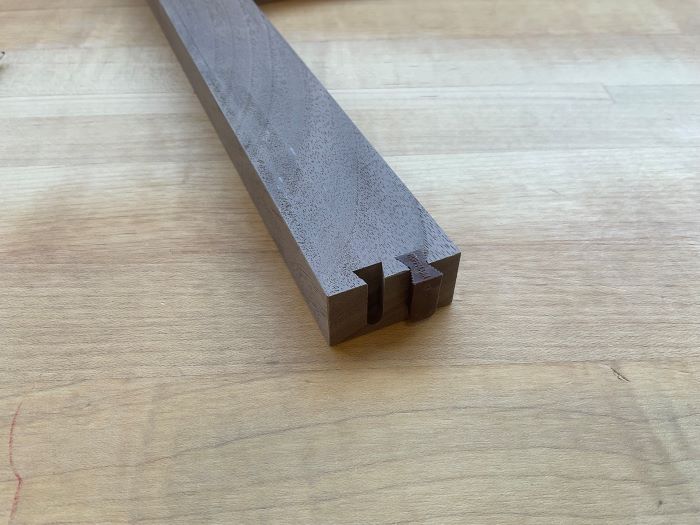

The general idea is to create two pins in alignment and use a “key” or two parallel tails to hold the joints together. The appealing part of the dovetail is being able to draw together the joint using the taper of the tails in relation to the opposing taper of the pin. The Hoffman Dovetail Machine is a specific tool for this joint, essentially a trim router attached to a fixed base. The magic of this tool is that it’s connected via a pneumatic lift that, while cutting, raises from below the table and makes an upcut into the underside of the part you are joining. A router shooting up from under a table into your workpiece can sound a little wild, but with a pneumatic hold-down and a foot pedal controlling the lift mechanism, you have both hands free to hold your workpiece. (Even though the pneumatic hold-down does most of the work).

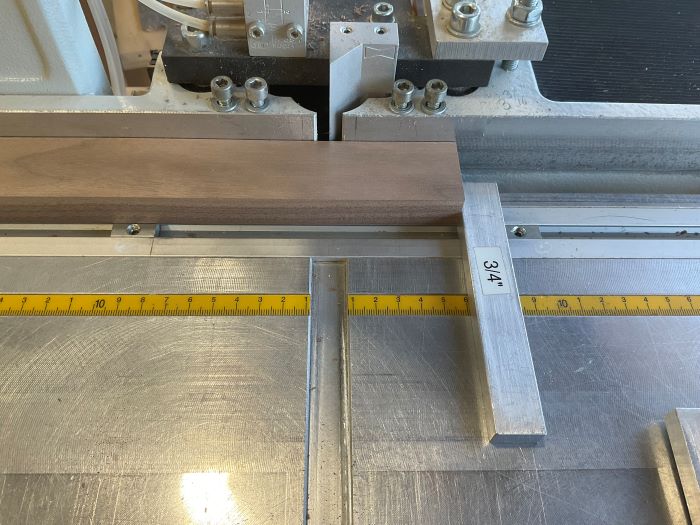

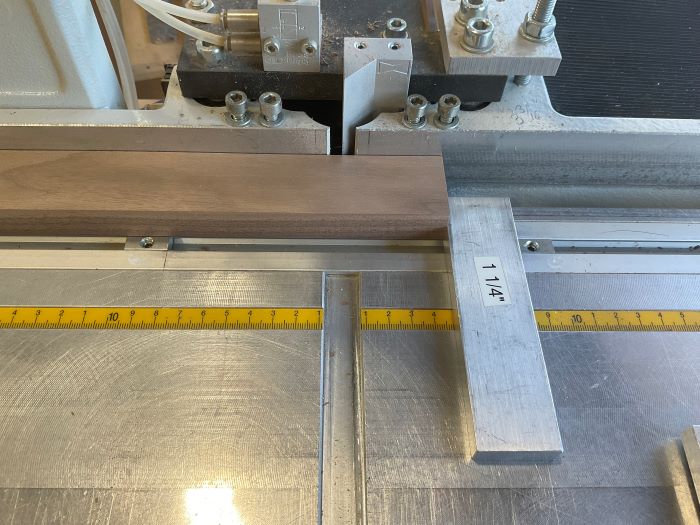

You could mark lines all day and cut to those based on the center of the cutter, but Hoffman designed a system of spacers that allows you to set different offsets to create easy spacing and reference points for consistent positioning of joinery. For example, I want to join the vertical face frame member to the cross member. By using the end grain of my cross member as a reference point on the spacers and the long grain of my vertical, I will create a perpendicular joint. If I used a long-grain edge for both parts, I would create a basic butt joint.

|

|

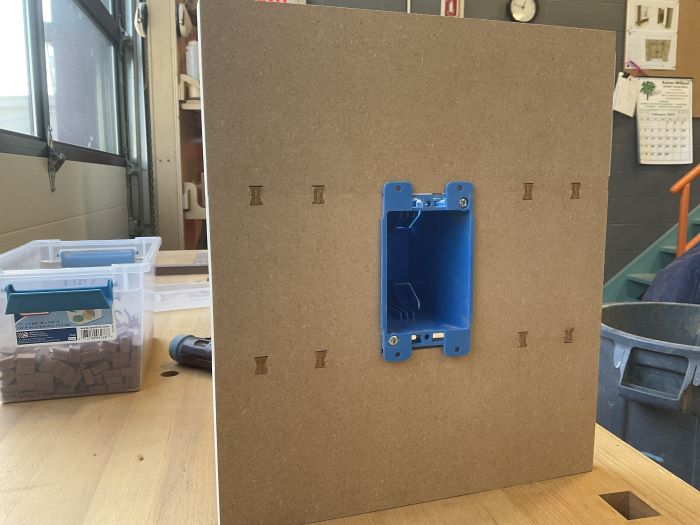

I have already mentioned how you use it for a face frame. This tool also makes short work of simple stick assembly, including miters. But there are a few more applications that make the Hoffman worth its space in the shop. I use it all the time for jigs! If I need to make a simple router template, say, to cut out an outlet, this is a straightforward way to join some boards together on the edge, keeping them flush and low profile. We often make larger assemblies, and my most valued technique for this application is to have the dovetails pre-loaded into a part already applied to the cabinet so when I go to join the other, instead of having to use a scarf joint or face nail the two parts, they will come together quickly and perfectly tight with the sturdiest possible joint.

The Hoffman Dovetail Machine definitely keeps its spot in the shop and will continue to. I think a lot of people will wonder if you could cut traditional-style dovetails with this, and you very easily could, but you are limited by the size of the bit included. For how well it works with what it’s set up to do, why mess with success?

Sign up for eletters today and get the latest techniques and how-to from Fine Woodworking, plus special offers.